Programmable logic controllers (PLCs) are essential in modern automation systems. Leadshine provides advanced solutions for various industrial applications. Choosing reliable PLC manufacturers is the first step to ensure compliance with safety and industry standards. By integrating robust hardware and software, industrial PLC systems can manage complex processes while meeting regulatory requirements.

Selecting Certified PLCs

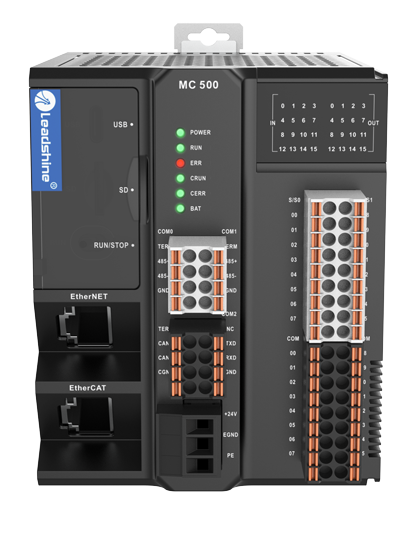

Safety begins with selecting PLCs that adhere to international standards. Among reputable PLC manufacturers, Leadshine offers the MC508CS, a versatile PLC featuring local 6-axis pulse output and support for 8-axis EtherCAT bus control. This device supports absolute and relative motion, speed, torque, jog control, E-CAM, and interpolation functions. Choosing PLC manufacturers that provide devices with these capabilities helps ensure operational safety, long-term reliability, and compliance with industry benchmarks.

Programming and Functional Compliance

Programming practices directly impact a PLC’s compliance. Leadshine supports programming languages including ST, LD, SFC, CFC, FBD, and IL. The MC508CS function libraries conform to the PLCopen standard, facilitating safer and standardized control logic. Ensuring proper configuration and using certified industrial PLC devices minimizes risks of malfunction or unsafe operations.

System Integration and Communication

Integrating industrial PLCs with drives and peripherals is crucial for safe and reliable operations. Leadshine devices such as the MC508CS function as an industrial PLC that matches CAN bus drives and expansion modules, supports dual RS-485 and RS-232 communication ports, and allows local back-panel BUS extensions for up to 32 R2 series modules. These features ensure seamless communication between system components and enhance safety by reducing wiring errors and unexpected behaviors in automated systems.

Conclusion: Best Practices for PLC Safety

To ensure PLCs comply with safety and industry standards, companies should select reputable PLC manufacturers, choose certified devices like Leadshine MC508CS, implement standardized programming practices, and integrate communication and control systems carefully. Following these steps ensures automation processes operate safely, reliably, and in accordance with industry requirements. By combining practical safety measures with advanced hardware, industrial operations can achieve efficient and compliant automation.