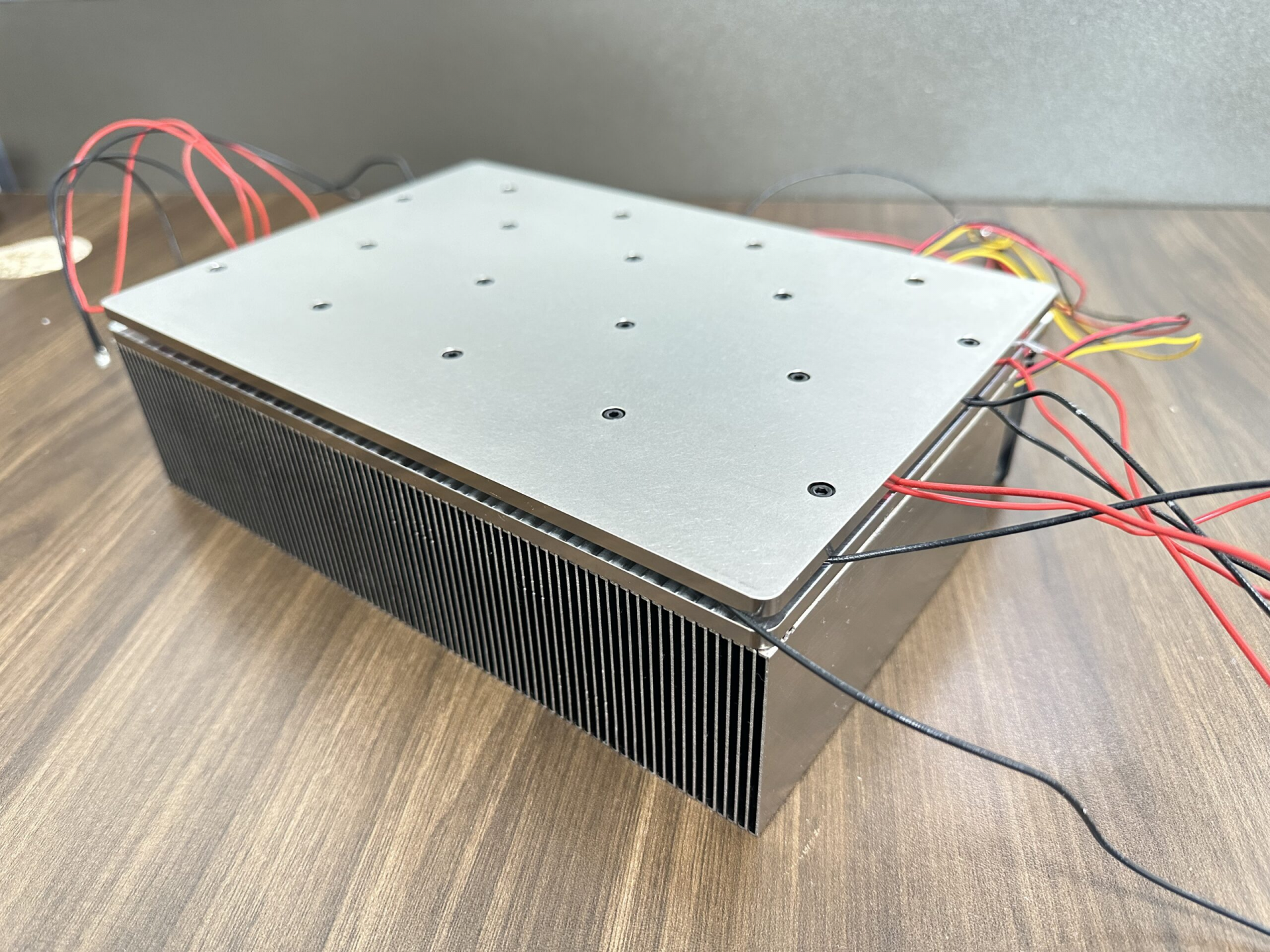

Stable thermal conditions are essential for electronics that operate in environments where heat fluctuations can influence performance. Engineers often turn to the thermoelectric cooling assembly because it provides controlled heat transfer without requiring mechanical refrigeration components. These assemblies rely on the Peltier effect, where electricity drives heat from one side of a module to the other. When companies such as Dingmetal design solutions using this principle, they focus on consistent operation, dependable structures, and low-maintenance features that meet industrial expectations. A thermoelectric cooling assembly is especially valued in systems where fast response times and predictable heat behavior are required to protect sensitive components.

How Assemblies Maintain Precision in Electronic Devices

Temperature stability is not simply a convenience—it is a core requirement for many categories of electronic equipment. This is where thermoelectric cooler assemblies help engineers maintain narrow temperature ranges. By combining thermoelectric modules with heat sinks, fans, or liquid cold plates, these assemblies form integrated cooling solutions that adapt to changing conditions. Providers like Dingmetal incorporate materials and structural designs that support steady heat movement and reduce thermal interference during operation. In communication modules, laboratory sensors, or compact industrial control units, thermoelectric cooler assemblies assist with maintaining accuracy by responding quickly to temperature changes and minimizing deviations that could impact performance or data reliability. Their solid-state nature also reduces vibration and noise, which is significant for delicate environments.

Product Features That Support Real Engineering Requirements

Thermoelectric Cooler Assemblies, powered by advanced Peltier technology, combine compact dimensions with consistent heating and cooling capability. These systems avoid refrigerants and compressors, making them easier to integrate into existing hardware structures. The absence of mechanical components in the thermal core allows the assembly to achieve reliable performance over extended operational periods. When manufacturers such as Dingmetal apply these features to real projects, they match the cooling characteristics of each thermoelectric cooling assembly to the device architecture and targeted thermal load. This helps engineers manage localized hot spots and maintain thermal balance in areas that are sensitive to variation.

In industrial automation, precision testing equipment, or optical instruments, thermoelectric cooler assemblies provide a steady method of temperature control where airflow is limited or where traditional cooling methods would be impractical. Their predictable output also makes system design easier, reducing concerns related to calibration drift or fluctuating heat transfer. With these characteristics, engineers can design equipment with improved operational stability and extended service life.

Conclusion: Practical Value of Thermoelectric Cooler Assemblies in Electronics

Across many engineering scenarios, thermoelectric cooler assemblies offer a practical combination of accuracy, consistency, and ease of integration. Solutions developed by Dingmetal apply solid-state thermal principles that support both high-performance electronics and everyday industrial modules, allowing engineers to manage temperature-sensitive components with greater confidence. When a thermoelectric cooling assembly is incorporated into a system, it helps maintain stable conditions without adding mechanical complexity or excessive maintenance demands, which is especially valuable in compact or tightly controlled environments. As electronics continue to become smaller and more advanced, assemblies that support precise temperature management will remain essential for ensuring dependable operation, long-term durability, and predictable performance across a wide range of specialized and continuously evolving applications.